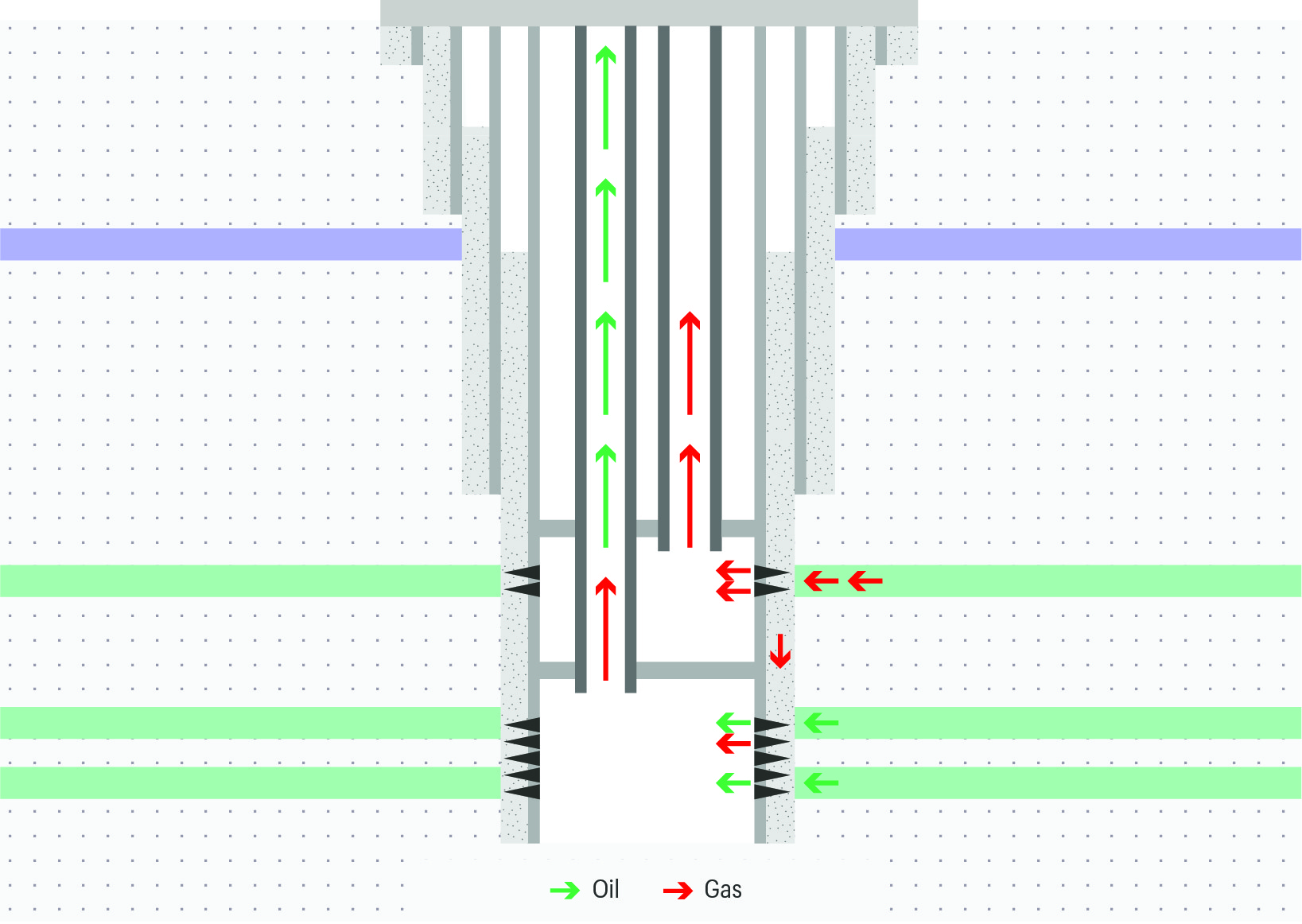

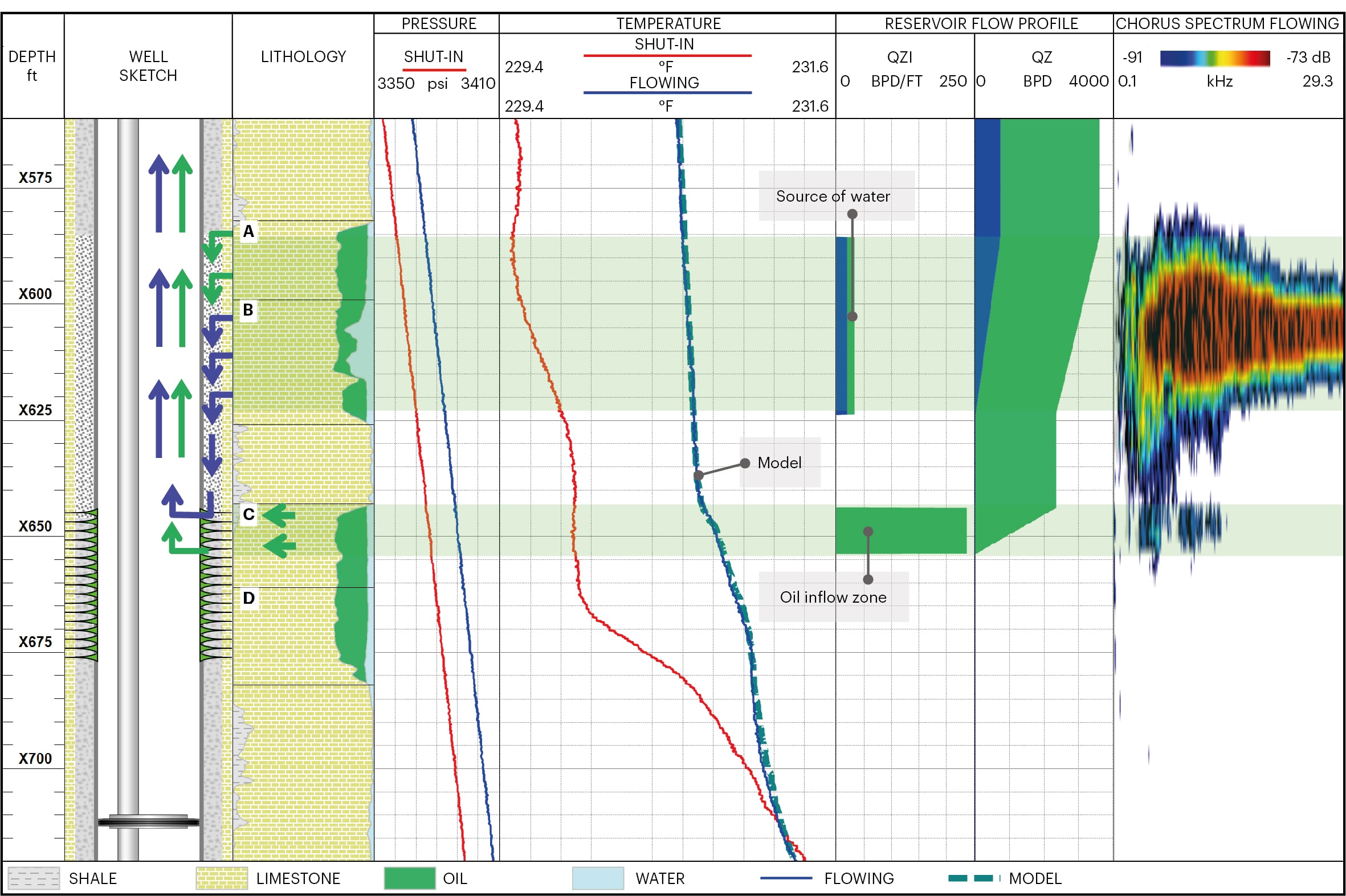

A dual-string completion is a cost-effective method for producing from multilayered reservoirs using a single wellbore. However, the perforation interval in the upper reservoir is not usually surveyed because of safety concerns about conventional tools becoming entangled around the long string as they exit below the short-string tubing shoe. An Abu Dhabi offshore well was drilled and completed as a dual-string producer in 2014. However, the well showed a 20%-water cut, presumably from the aquifer. The principal challenge was to evaluate the production profile in the short string and find the true source of water. This would require a diagnostic platform with a depth of investigation that extended beyond the tubing.

- Location Abu Dhabi

- Well Type Dual-string oil producer

- Reference SPE-182889

-

Evaluated the short-string production profile in a dual-completion well

-

Identified crossflow behind casing

-

Located and quantified source of water

-

Enabled the operator to adjust and optimize workover plans