Two other challenges to well integrity today – both interlinked – are that of well cementing and sustained annulus pressure [SAP].

As operators look to deeper and longer reach wells, cementing techniques and sealing abilities have been pushed to the limit. According to the Society of Petroleum Engineers [SPE], at least 25-30% of wells are estimated to have annular pressure problems with cementing being one of the root causes. One outcome of this is SAP – pressure in any well annulus that rebuilds when bled down.

SAP is often the result of weaknesses in the cement during completion; or cement degradation due to thermal and pressure loading; leaking tubing connections or wellhead seals; and corrosion. According to a 2013 SPE webinar on wellbore integrity [Paul Hopmans], out of ~1.8 million wells worldwide, a staggering 35% have SAP.

So how can well cementing and SAP be addressed?

To date, conventional means of tracking poor cementing and SAP is through surface measurements, such as fluid sampling, bleed-off/build-up data and downhole measurements such as ‘cement bond logs’, temperature and ordinary noise logs. This, however, only provides limited information and may be unable to locate leaks and unwanted flowpaths behind multiple barriers – especially when the leak rate is low.

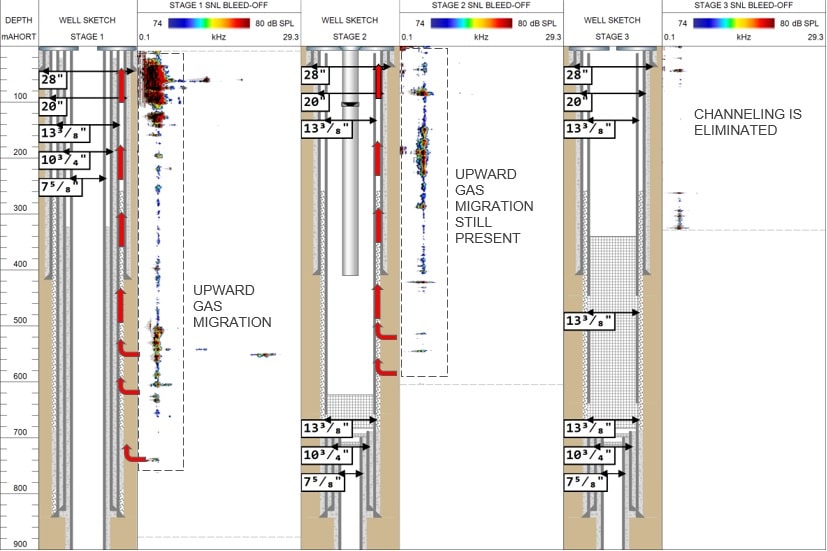

To address this information gap, TGT’s ‘spectral diagnostics’ technology tracks fluid movement behind pipes from within several casing strings. This is achieved using high-fidelity downhole sound analysis systems to capture the frequency and amplitude of acoustic energy generated by liquids or gas moving through integrity breaches and restrictions. Complementing this, spectral diagnostic systems utilise high-precision temperature measurements to help locate integrity breaches throughout the well system.

While conventional production logging measurements typically assess only high-rate first-barrier failures – the high-fidelity recording, sensitivity and clarity of spectral diagnostics enables the tracking of even low-rate leaks at very early stages behind multiple barriers, thereby enabling timely intervention.

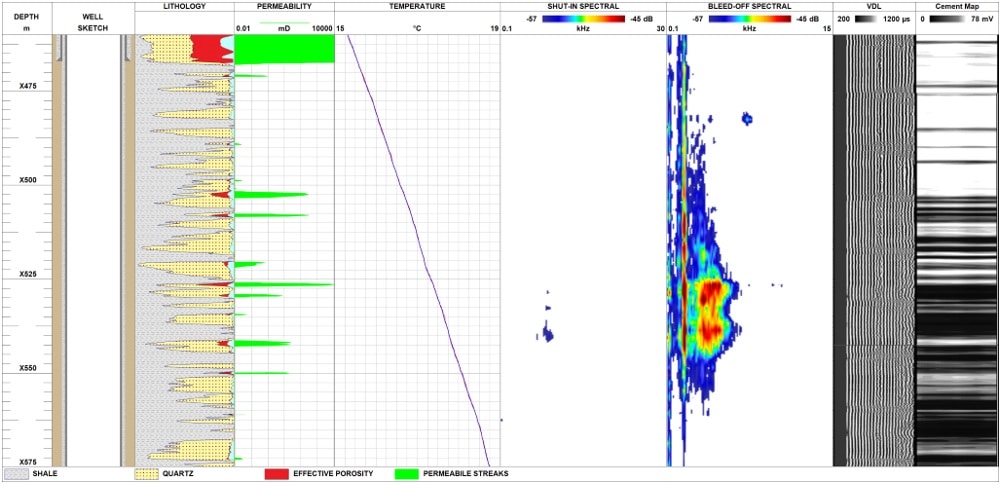

In figure 2, a water injector well experienced sustained B-annulus pressure, although the build-up rate did not exceed one bar a day – indicating a low-rate leak. A cement bond survey indicated good cement bonding below X500m, and poor bonding above, likely to provide flowpaths for fluid movement behind casing.

A survey utilising TGT’s spectral diagnostics system was conducted and revealed fluid flow from the reservoir around X540m and channelling up the annulus through the incorrectly assumed ‘good bonding’ area.

The frequency spectrum pattern correlated with reservoir permeability and fluid-type profiles, suggesting gas was being produced from these formations. The operator used the information to target a cement squeeze operation at the desired location in the well – restoring B-annulus integrity and eliminating the SAP.